| Product Description |

| Place of Origin | Zhejiang, China (Mainland) |

| Brand Name | MaGenesis |

| Model Number | Various |

| Type | Permanent |

| Composite | NdFeB Magnet |

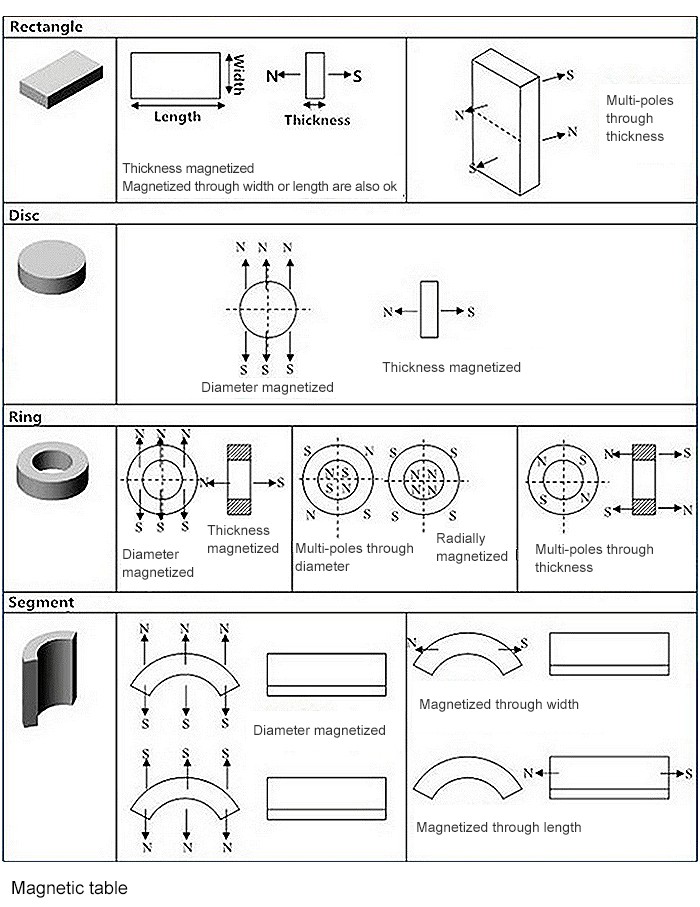

| Shape | Disc,Cylinder,Block,Ring,Countersunk,Segment,Trapezoid, Ir-regular shapes and more custom shapes |

| Application | Neodymium magnet raw magnetrials are widely used in industrial field,such as mobile phones, wind power generations, magnetic resonance equipment, toys, digital cameras, speaker,louder speaker,sensor,motor,alternator, stationery ect; And also it is popular in ladies bags,purses,shoes,crafts and jewelry ect. |

| Technology | We have advanced R&D center in Wuhan City with RMB 20 million investment amount, serious quality control and professional machining technicians |

| Magnetize direction | Customized |

| Size | Customized |

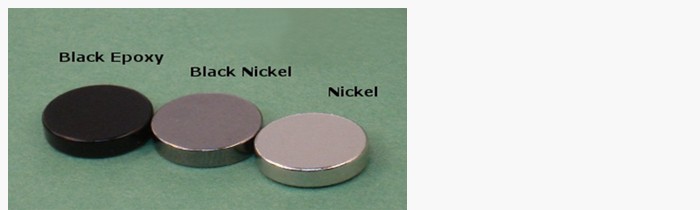

| Coating | Ni, Zn, gold, silver, copper, epoxy, and so on |

| Tolerance | +/-0.03 to +/-0.15 |

| Certificate | ISO/TS16949,Rohs, EN-71, REACH |

| Working temperature | The max operation temp is up to 230 degree centigrade |

| Delivery | By sea, by air, or by express |

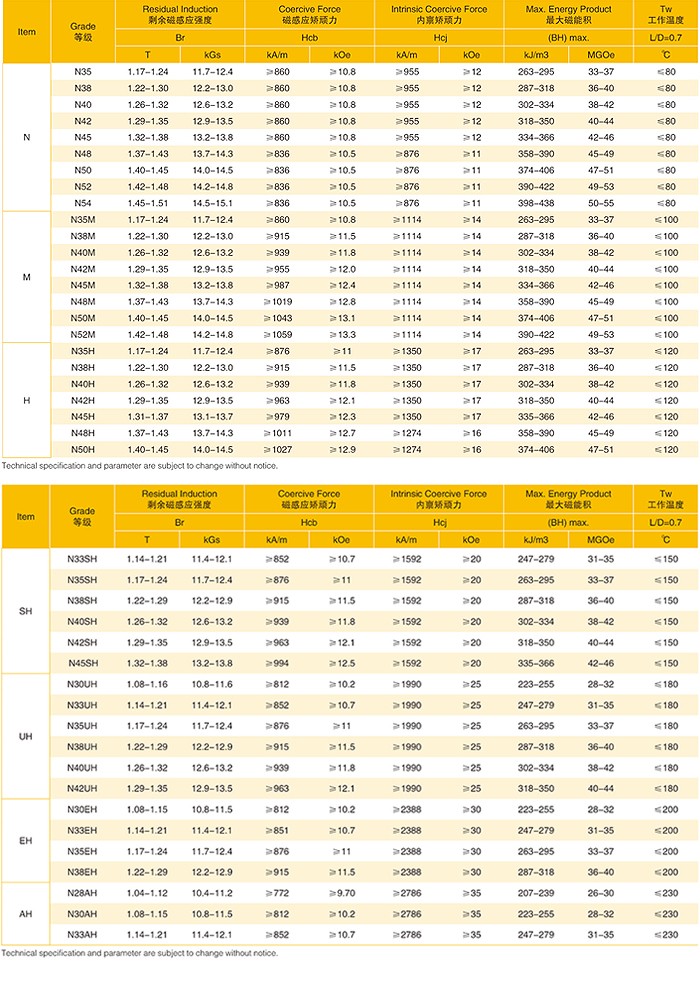

| Max Working Temperature |

Grade |

| N33-N52 80°C | |

| N35M-N45M 100°C | |

| N33H-N50H 120°C | |

| N33SH-N45SH 150°C | |

| N30UH-N42UH 180°C | |

| N30EH-N38EH 200°C | |

| N28AH-N33AH 230°C |

| MOQ | 100 pieces as sample |

| Sample Policy | Sample fee accordingly and freight paid by customers |

| Sample Lead Time | Within 5-10 days |

| Packing Details | Anti-magnetism packing |

| Bulk Manufacture Time | 8-25 days |

| Delivery Time | Within 5 days by DHL;Within 30 days by Sea |

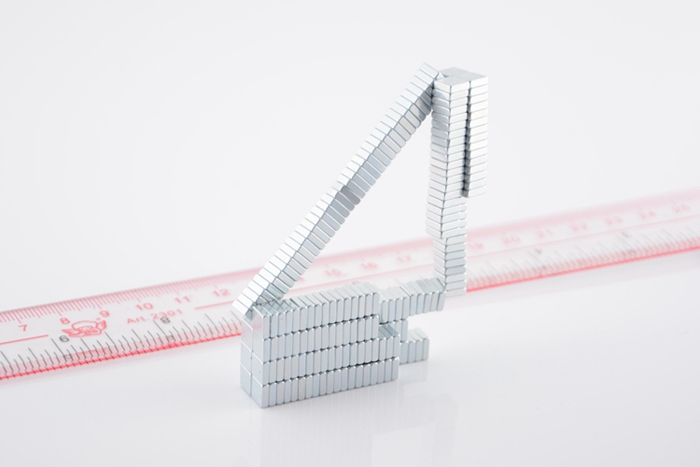

| Product Display |

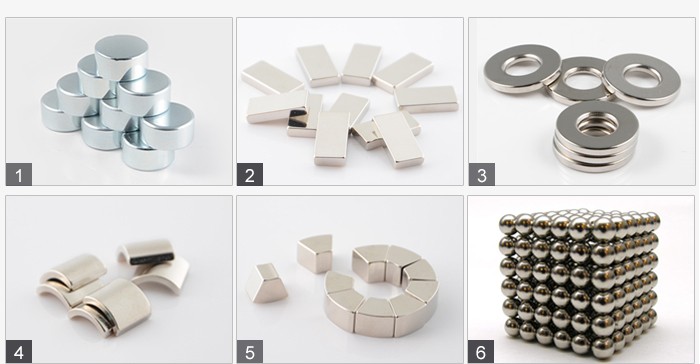

| Product Categories |

| 1.Disc >> | 2.Block >> | 3.Ring >> | 4.Tile >> | 5.Abnomity >> | 6.Ball >> |

| Product Application |

| Our Equipment |

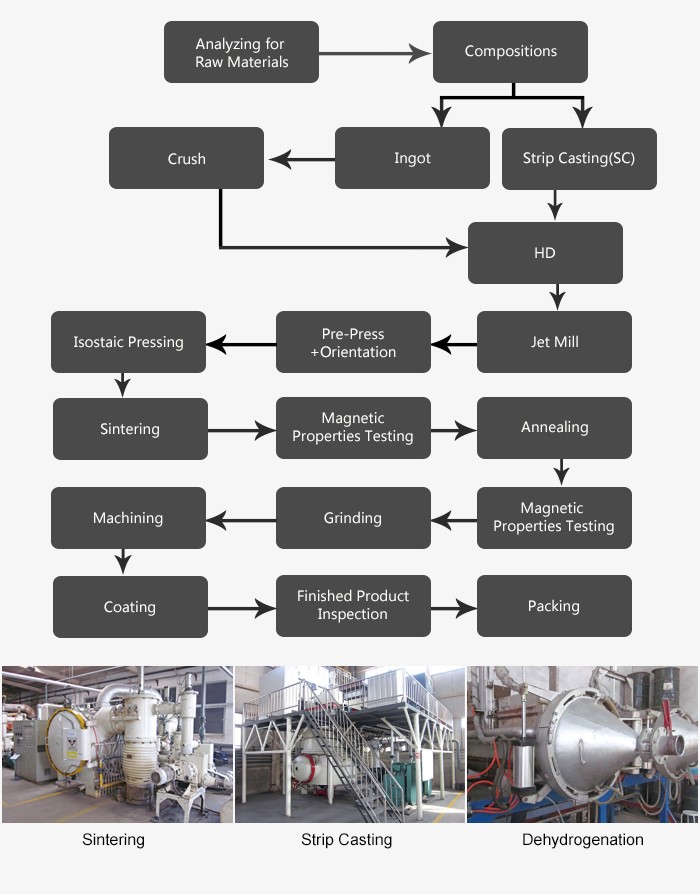

| Production Process |

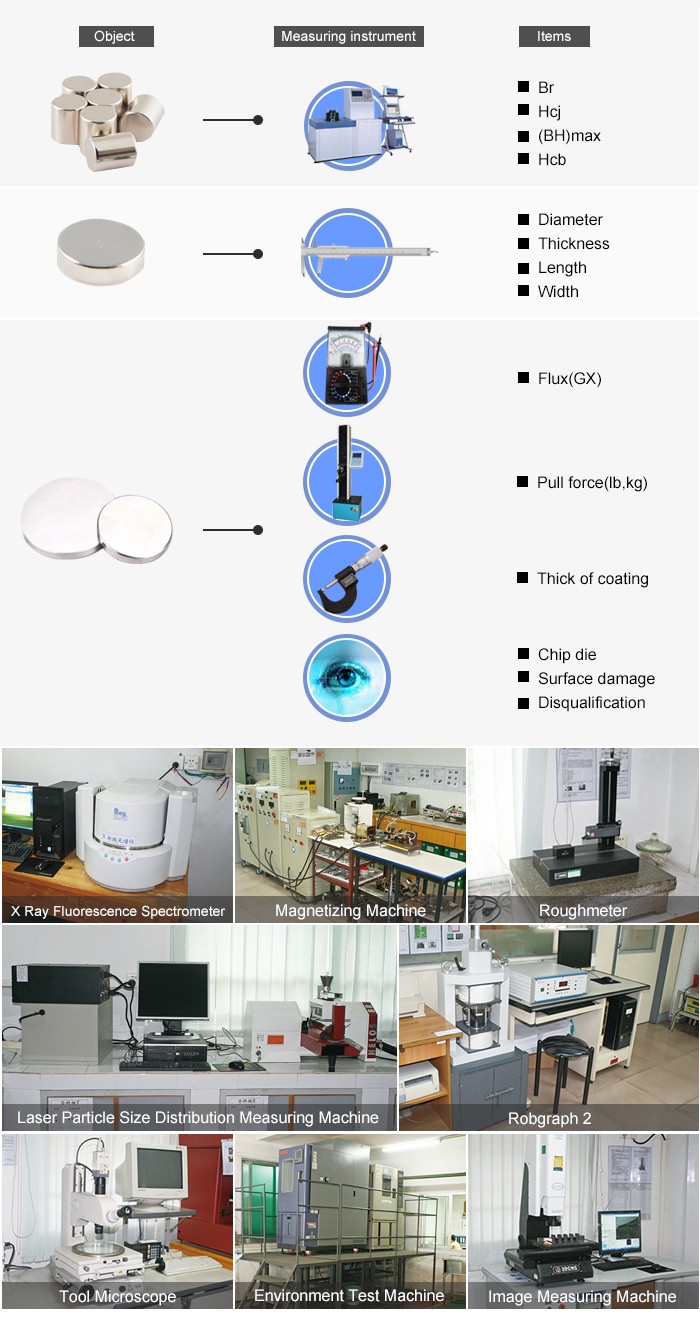

| Quality Control |

| Magnetization Direction |

| Partner Customers |

| Our Certificate |

| Our Transport |

| FAQ |

| 1. Is one pole stronger than the other? |

| No, both poles are equally strong. |

| 2. Which is the strongest type of magnet? |

| Neodymium (more precisely Neodymium-Iron-Boron) magnets are the strongest permanent magnets in the world. |

| 3. I need a special size/shape of neodymium magnet. Can you supply custom magnets? |

| Yes, we can supply custom magnets. You can find details on our Custom Magnet Page. |

| 4. What materials do magnets attract? |

| Ferromagnetic materials are strongly attracted by a magnetic force. The elements iron (Fe), nickel (Ni), and cobalt (Co) are the most commonly available elements. Steel is ferromagnetic because it is an alloy of iron and other metals. |

| 5. Can you supply a disc/cylinder/ring/sphere magnet with one pole on the outside and one on the inside? |

| Disc, cylinder, and sphere shapes definitely cannot be manufactured this way. Rings magnetized this way are referred to as "radially magnetized", but it is not currently possible to manufacture neodymium ring magnets this way. We are working on it, however. |

| 6. What are neodymium magnets? Are they the same as "rare earth"? |

| Neodymium magnets are a member of the rare earth magnet family. They are called "rare earth" because neodymium is a member of the "rare earth" elements on the periodic table. Neodymium magnets are the strongest of the rare earth magnets and the strongest permanent magnets in the world. |

| 7. What are the size limitations on manufacturing neodymium magnets? |

| The limits include: 2" max in magnetized direction 4" max diameter for discs and rings 4" max length and width for blocks 1/32" minimum on thickness on any magnet 1/16" minimum diameter on outer diameter 1/16" minimum diameter on any hole |

| 8. Do I have to worry about temperature with neodymium magnets? |

| Yes. Neodymium Iron Boron magnets are sensitive to heat. If a magnet heated above its maximum operating temperature (176°F (80°C) for standard N grades) the magnet will permanently lose a fraction of its magnetic strength. If they are heated above their Curie temperature (590°F (310°C) for standard N grades), they will lose all of their magnetic properties. Different grades of neodymium different maximum operating and Curie temperatures. See our Neodymium Magnet Specifications Page for more details. We do stock a range of high temperature magnets, which you can see here. |

| 9. What does "Magnetized thru thickness" mean? |

| We use the description "Magnetized thru thickness" to identify the locations of the poles on our block magnets. The thickness is always the last dimension listed for block magnets. If you take one of our block magnets and place it on a flat surface with the thickness dimension as the vertical dimension, the poles will be on the top and bottom of the magnet as it sits. For example: Our BX082 blocks are 1" x 1/2" x 1/8" thick. If you place one of the blocks so it is on a flat surface with 1/8" as the vertical dimension, the poles will be on the top and bottom as the magnet sits. This means the poles are located in the middle of the 1" x 1/2" sides. Click here for Magnetization Directions Illustrated. |

| 10. What is the gauss rating of your magnets? |

| This depends on the context it is used. Most magnetic therapy people like to present the largest number possible, so they often use the Residual Flux Density (Brmax) of the material, which really doesn't specify much about the actual magnet. This value is essentially the magnetic field density inside the magnet material. Since you will never be inside the magnet, or using the field inside the magnet, this value doesn't really have any practical value. The surface field of a magnet is a much more accurate specification for a magnet. The surface field is exactly what it sounds like. It is the magnetic field density at the surface of the magnet as measured by a Gaussmeter. This value is tested and specified for each of our stock magnets. A comprehensive table of the surface field density for each of our stock magnets can be seen here: Magnet Summary Table. |

| 11. How can I identify the poles of the magnets? |

| There are several simple methods that can be used to identify the (Scientific) North and South poles of neodymium magnets. 1) The easiest way is to use another magnet that is already marked. The North pole of the marked magnet will be attracted to the South pole of the unmarked magnet. 2) If you take an even number of magnets and pinch a string in the middle of the stack and dangle the magnets so they can freely rotate on the string, the North pole of the magnets will eventually settle pointing North. This actually contradicts the "opposites attract" rule of magnetism, but the naming convention of the poles is a carry over from the old days when the poles were called the "North-seeking" and "South-seeking" poles. These were shortened over time to the "North" and "South" poles that we know them as. 3) If you have a compass handy, the end of the needle that normally points North will be attracted to the South pole of the neodymium magnet. 4) Use one of our Pole Identifier Devices. (Please note: In some magnetic therapy applications, the definitions of the poles are reversed from the scientific definition described above. Please be sure to confirm the proper definition of the poles prior to using magnets for medical purposes)vinyl magnet Also check out our article, Which Pole is North? |

| 12. What is the difference between the different platings and coatings? |

|

| Choosing different coatings does not affect the magnetic strength or performance of the magnet, except for our Plastic and Rubber Coated Magnets. The preferred coating is dictated by preference or intended application. More detailed specifications can be found on our Specs page. • Nickel is the most common choice for plating neodymium magnets. It is actually a triple plating of nickel-copper-nickel. It has a shiny silver finish and has good resistance to corrosion in many applications. It is not waterproof. • Black nickel has a shiny appearance in a charcoal or gunmetal color. A black dye is added to the final nickel plating process of the triple plating of nickel-copper-black nickel. NOTE: It does not appear completely black like epoxy coatings. It is also still shiny, much like plain nickel plated magnets. • Zinc has a dull gray/bluish finish, that is more susceptible to corrosion than nickel. Zinc can leave a black residue on hands and other items. • Epoxy is basically a plastic coating that is more corrosion resistant as long as the coating is intact. It is easily scratched. From our experience, it is the least durable of the available coatings. • Gold plating is applied over the top of standard nickel plating. Gold plated magnets have the same characteristics as nickel plated ones, but with a gold finish. |